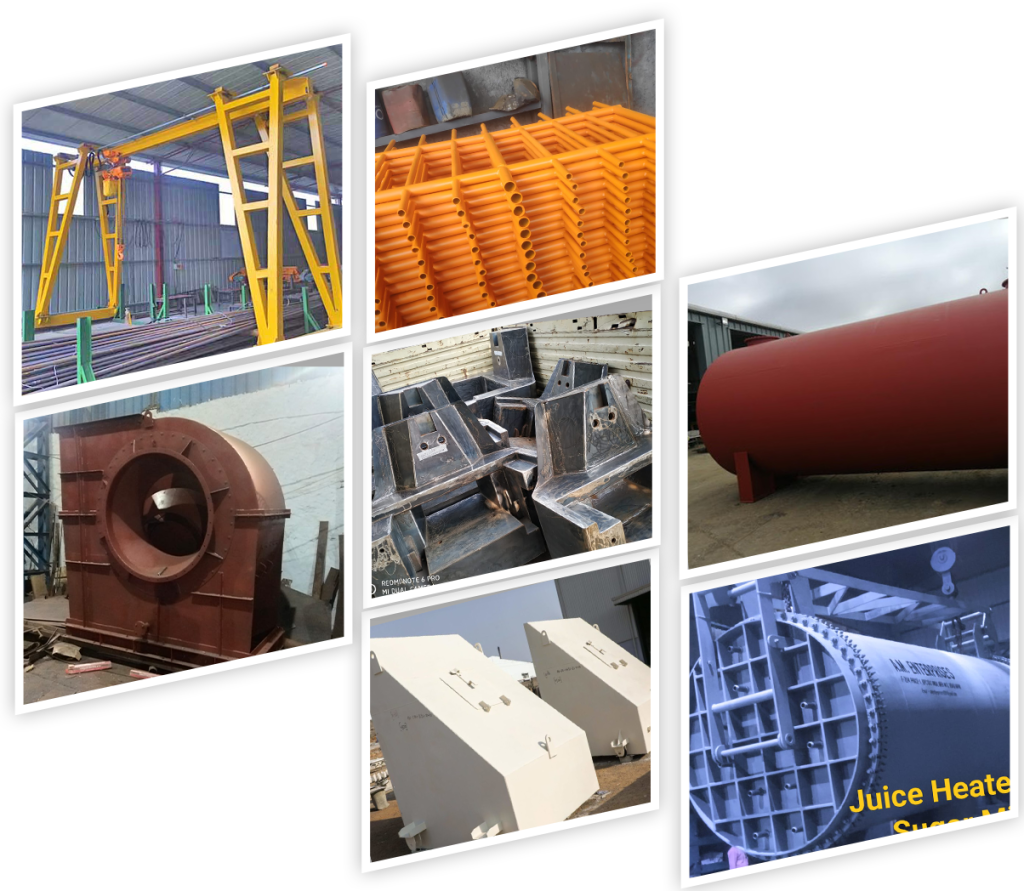

TBE Quality Control function is to develop and implement an integrated sequence or specific control on quality relative to materials, process and product based on quality aspects of industry specifications and customer requirements, design specifications and manufacturing process requirements to assure a timely shipment of products with proper quality at relatively minimum costs.

Top quality raw materials are used to manufacture metal components for steel structures or heavy steel work. The company has a better control of its finished products with its parts checking system. It ensures that the product is ready for its intended use at the job site without modification.

A quality management strategy to decrease the wastage is used to define the quality techniques and standards to be applied for achieving the required quality level by quality management strategy:

- Procedures

- Tools and techniques.

- Records reporting.

- Timing of quality activities.

- Roles and responsibility

The Company’s quality objectives shall ensure that business development, procurement, fabrication, testing and inspection activities undertaken on any given project are:

- Planned and performed to achieve the required quality within budget and schedule requirements.

- In accordance with contractual and regulatory requirements.

- Performed correctly the first time to ensure cost effectiveness and efficiency.

We understand the importance of quality products and the long way it goes in establishing a name as a brand. To achieve this goal, we have set rigorous quality control procedures at different stages of sourcing of raw material, production and supply. International practices and methods are adopted to produce international standard products.